How to build your own electric car for £10,000 (msn.com)

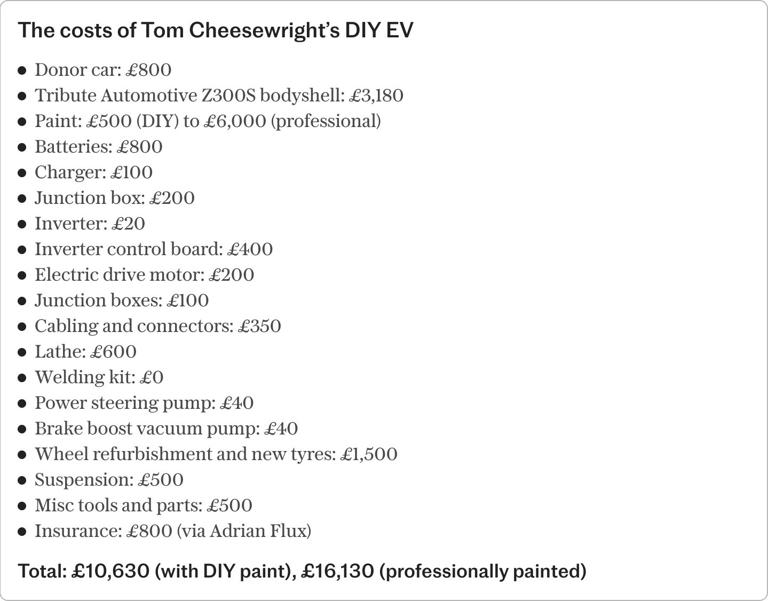

Which you might consider to be a drop in the ocean of the cost of building a DIY EV. Also, parts were surprisingly inexpensive: the batteries cost £800, the charger £100, junction box £200, inverter £20, the motor £200. Two junction boxes cost £100, and cabling £350.

The electronic “brain” of the new powertrain came from software specialist EV BMW, one of the many members of the EV geek community who exchange learning and expertise. It attaches to the inverter and controls power distribution. That control board cost £400.

Cheesewright fabricated various components to connect the motor, gearbox and back axle. He had most of the right tools, but bought a lathe for £600 to machine parts, then resuscitated welding equipment that had been discarded by a local garage.

Non-EV parts included a £40 Vauxhall power steering pump, £40 Audi brake boost vacuum pump and a battery box made from an old washing machine.

That’s just as well, because his garden-build EV features batteries from a BMW 330e, the electric motor and battery charger from a Mitsubishi Outlander PHEV, electrical current inverter from a Toyota Prius, as well as a heater from the Mitsubishi to replace the BMW’s engine-warmed unit, along with a high-voltage junction box from a local electrical supplier.

The power, an electrical equivalent of the BMW’s original 140bhp, finds its way to the road via the BMW’s original gearbox and rear axle.